News

Northwestern-invented biomaterial technology moves from lab bench to the orthopaedic market

September 23, 2021

Resorbable anti-inflammatory tendon fixation technology used in patients for the first time

Northwestern biomedical engineer Guillermo A. Ameer has achieved a rare, major accomplishment. A medical product based on novel biomaterials pioneered in his laboratory will be widely available for use in musculoskeletal surgeries to directly benefit patients.

The biomaterial technology, called CITREGEN™, developed by the start-up company Acuitive Technologies, Inc., is featured in Stryker Corporation’s CITRELOCK™, an innovative device that will debut this week at the American Orthopaedic Foot and Ankle Society’s annual meeting in Charlotte, N.C. The CITRELOCK™ Tendon Fixation Device System is used to attach soft tissue grafts to bone in reconstruction surgeries and provides surgeons a differentiated design due to Ameer’s biomaterial.

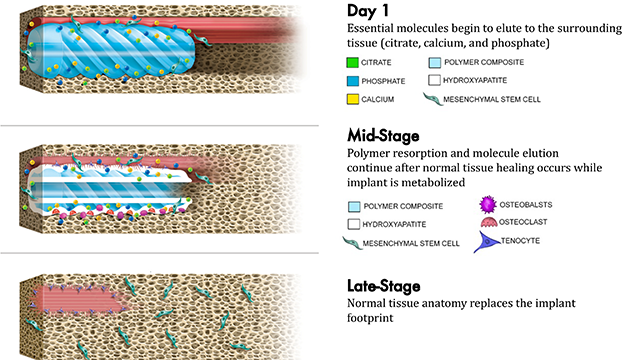

CITREGEN™ has unique chemical and mechanical properties for orthopaedic surgical applications that help grafted tissue heal. It contains organic molecules and includes citrate, phosphate and calcium, components that are essential to healthy bone growth. CITREGEN™ is the first thermoset biodegradable synthetic polymer ever used in implantable medical devices.

The implantable device, CITRELOCK™, received clearance from the Food and Drug Administration (FDA) last year. The CITRELOCK™ device has a compressive strength comparable to cortical bone and maintains structural integrity during the healing phase, while allowing the implant to be remodeled by host tissue over time.

The founding director of Northwestern’s Center for Advanced Regenerative Engineering (CARE) and director of a recently established Regenerative Engineering Training Program funded by the National Institutes of Health, Ameer is on a mission to use engineering and workforce training to enable the practice of regenerative medicine to improve the outcome of surgeries and benefit patients. But typically, medical technologies derived from academic research take years to be adopted by a company, and over a decade to receive clearance or approval from regulatory agencies such as the FDA.

CITREGEN™ is the third Northwestern technology medical technology company Stryker has brought to the market. A robotic arm invented by Michael Peshkin in 1997 made it to orthopedic markets after Stryker bought his medical device company, Mako, in 2013. And former Northwestern dental school professor Richard Wixson’s cement mixer was purchased and developed by Stryker, too.

“Citregen is an exciting addition to Stryker’s existing biomaterial portfolio and will be expanded for use in additional trauma and extremities indications in the future,” said Michael Rankin, vice president of marketing and medical education of Stryker’s foot and ankle business.

Enabled by collaboration

Ameer, the Daniel Hale Williams Professor of Biomedical Engineering in Northwestern’s McCormick School of Engineering and professor of surgery in Northwestern’s Feinberg School of Medicine, reflects on the almost 20 years he and his teams have spent developing the innovative biomaterial technology.

“When I first started my lab years ago here at Northwestern, one of my major goals was to use engineering to have a positive impact on patient care. That goal has been a guiding principle for my research. I sought to work with surgeons to fully understand medical problems, patient needs, constraints and come up with solutions,” Ameer said.

“We first developed our citrate-based polymers 18 or so years ago and initially researched applications in vascular and orthopaedic tissue engineering. For the latter, we created composites which are a mixture of the polymer and a ceramic, the foundation for CITREGEN.™ The first publication of those composites for bone regeneration, in collaboration with orthopaedic surgeon Dr. Jason Koh, was in the journal Biomaterials in 2006. Our work has been expanded upon by other researchers around the world, perhaps most notably my former postdoctoral trainee Jian Yang, now the Dorothy Foehr Huck and J. Lloyd Huck Chair in Regenerative Engineering at Pennsylvania State University.

“A decade later, through collaborations with industry, we were able to jump-start the translation process to use our polymer technology in innovative bioresorbable orthopaedic devices. Even though 20 years seems like a long time to see our technology get to market, we are fortunate to achieve this milestone in my academic career.”

On searching for new materials: “What drove the development of citrate-based polymers and composites was the need to work with materials that were elastic like rubber, easy to tailor, could support cell functions, but also would safely dissolve away in the body while being replaced with normal tissue — as no such material existed at the time. Working with an excellent team of students and postdocs, we invented a material taking into account a variety of requirements from the start. These included the body’s mechanism for degradation, ability to synthesize easily and with safe components, and modularity to control material properties for a variety of potential applications. Throughout the years, we and others have demonstrated that citrate-based polymer can be engineered into devices that help regenerate blood vessels, skin, heart, cartilage, bone, bladder and muscle tissues.”

On demand for better devices: “There is a demand from surgeons and patients for better bioresorbable devices, ones that promote tissue regeneration or at least would not interfere with it. It is not easy to introduce new devices built with new bioresorbable polymers in the market due to problems with implants made from traditional biodegradable polymers and the scrutiny from regulatory agencies when reviewing new bioresorbable devices. It was a long process but well worth it to bring new solutions to the market through established medical device companies.”

On taking risks: “Although we pioneered and have been working on this biomaterial technology for almost 20 years, significant credit goes to visionary individuals from industry, specifically Acuitive Technologies and Stryker, for recognizing the potential of our technology and investing resources for its development and validation. It took Acuitive six years to develop CITREGEN™ into useful products. The collaborations and partnerships that CARE has formed are important to replicating CITREGEN’s™ success in other health applications and translating into clinical practice other types of regenerative engineering technologies in the future.”

Ameer’s work has been recognized recently with the 2021 Clemson Award for Contributions to the Literature and numerous other honors, including being elected Fellow of the Biomedical Engineering Society, American Institute of Chemical Engineers, Materials Research Society, American Institute of Medical and Biological Engineering, American Association for the Advancement of Science and the National Academy of Inventors.

Ameer also is a member of the Simpson Querrey Institute, Chemistry of Life Processes Institute and International Institute for Nanotechnology.

Editor’s note: Ameer and Northwestern have financial interest in VesselTek BioMedical — the startup the technology was first licensed to. Ameer also serves on the Scientific Advisory Board of Acuitive Technologies.